Winter Cover finally sees

the light after two years!

the light after two years!

Winter Cover finally sees

the light after two years!

the light after two years!

There are so many stories I want to tell, from the Konny Mom’s Wear to the Konny Baby Carrier Summer, which were all made during the same two years of developing the Konny Baby Carrier Winter Cover. But since I already told you about the cover in the last episode, let me first tell you about how I eventually launched the baby carrier cover.

The first half of 2018 was quite hectic, developing the summer version of the baby carrier. After trying 20 different fabrics for the Konny Baby Carrier Summer, I ended up pushing back the launch of the product to ensure quality. (You know, completeness takes priority over how quickly you launch the product.) After dropping two items in a row, I started to wonder if I could really get this done right. But I couldn't just sit there feeling frustrated. Whether or not I was feeling down, the winter season was approaching. And I really wanted to succeed this time.

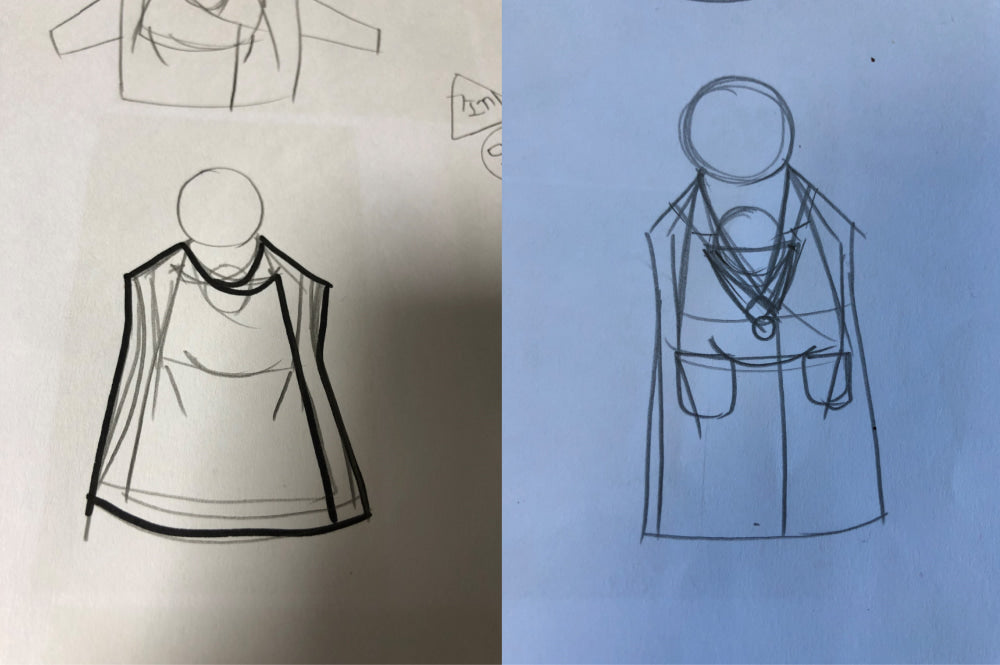

The first garment pattern of the Konny Baby Carrier Winter Cover. I kept wearing it, trying to figure out the problem.

Starting to work on the baby carrier cover once again, I slowly dwelled on why I failed to develop and launch it in the prior year. And I figured that the problem arose from working with the production agency in developing the product. Back in 2017, I decided to get help from the agency to save time and effort to produce the baby carrier cover. I set out the direction in detail, and the agency followed it and reflected my comments in developing the garment pattern and making adjustments. I thought I was headed in the right direction, because I lacked what the agency had in terms of rich experience and deeper understanding in sewing, fabrics, materials and the market. Everytime we had a meeting, I felt things were moving forward, definitely at a faster pace than when working alone.

But the real problem of working with the agency was that there was nothing left for me to do. As a person who lacked knowledge and experience in the field, I had to learn and gain confidence through researching, formulating hypotheses, verifying them, finding the right material by doing the legwork in the market, making sample patterns myself, touching them with my own hands, draping them over me, and trying them on myself. (I know, I am a slow learner.) I kept questioning whether a consumer would be willing to pay for this product. It may take longer, but the results gained after this thorough process of deliberation truly helps me be confident about my choice and my product more than anybody else (as I feel the same for the Konny Baby Carrier and the Konny Mom’s Wear).

But when working with a production agency, I did not have a chance to learn and gain confidence; because most of the decisions were made in the boundary of their suggestions. When I proposed a unit price for the product, they took the margins out and chose a fabric and subsidiary materials within the remaining budget. “Is there an alternative? I want it to be softer and snugger.” When I asked, their responses were like, “Then the unit price won't work” or, “This is the best quality fabric we can find in the market. Most other brands use materials of about this quality.” Of course, I wasn't satisfied with their response.

‘When developing something, I shouldn't try to save time, cost and effort. They will eventually be saved as I gain more experience in the field.’

Idea sketch. Between the cardigan type (left) and the coat type (right), I chose to go with the left one.

So, I made up my mind to build from scratch and work on the sample pattern for 2018. I called the artisan seamstress at the sample room who was in charge of making the Konny Baby Carrier. “It may take long, but there is a product I want to make right. I'll find and send nice fabrics over to your workroom.” I visited the wholesale fabric market and collected all the fabrics that looked nice to me, ranging from mustang leather to fleece to double-sided fabric to cashmere fabric for overcoats to Velboa fabric. I bought in almost every fabric used for winter overcoats. And after much consultation with the seamstress at the sample room on the design, I finally picked out the fabric for the baby carrier cover. “You are gifted in picking out a good fabric. I think this is a real good choice.” I was really happy to hear the compliment from the seamstress who has made luxury clothes for almost her entire life.

When designing the winter cover, my utmost mission was to make it light to go out with the baby in the winter. I wanted to design a baby carrier cover that is not cumbersome to wear and wonderfully does its job to keep the baby warm, while the design is nice and stylish enough to wear even without a baby, just like th Konny Baby Carrier. I wanted to make sure that our customers were spending money on what they can always wear in their daily lives, not on some unnecessary luxury goods. So, the cover needed to look similar to other ready-to-wear clothes. These were the specific details of the winter cover I had in mind. To make one like that, I needed to completely get the image of other baby carrier covers on the market out of my head, and start over.

The first sample made in 2018. The overlapping layers made the front too long, and the back too short. The shoulder line was also placed low on the front.

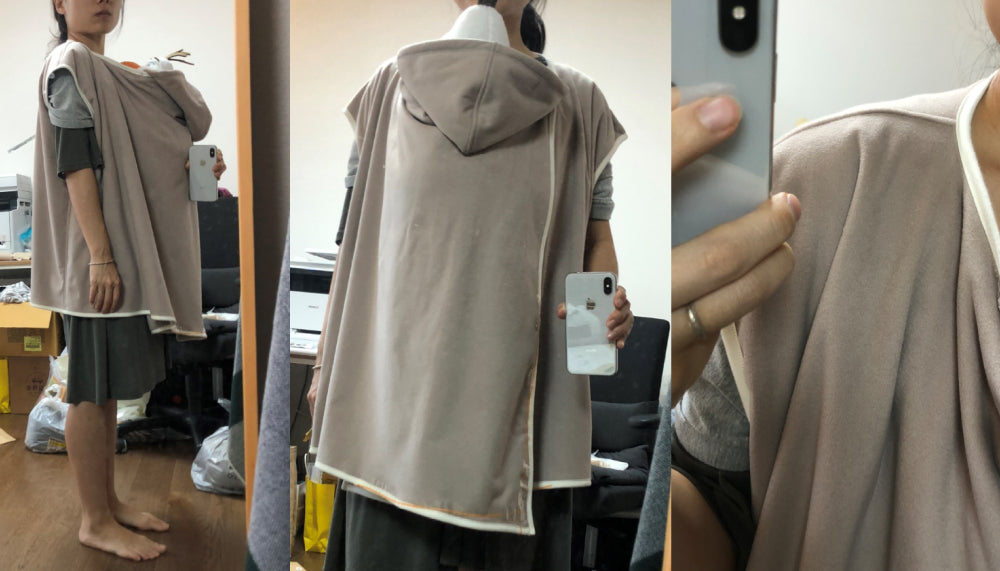

Discussing where to place the pockets and comparing with those of other baby carrier covers

Testing whether the shoulder part feels comfortable and not bulky under the overcoat, and the size and shape of the hoodie look nice.

Testing whether the shoulder part feels comfortable and not bulky under the overcoat, and the size and shape of the hoodie look nice.

A product like the Konny Baby Carrier Winter Cover did not exist in the first place, and there was nothing similar to refer to. So, it literally took months to develop a sample. Once the sample was made, I first tried it on myself, sent it over to other team members, and made adjustments based on the feedback. It took one to two weeks just to make changes to the sample. That year, we had a designer with ten years of relevant experience in the field. I was beating my head against the wall each day, going back and forth to the sample room with the designer. One day, she laughed and said, “I've never seen a person who makes clothes like you. How many times are you revisiting the original pattern to make adjustments?”

Back then, I did not have much understanding on the process of garment making. Normally, you form a rough shape of the clothes and do fitting using an easily breakable thread. Next, you decide where to make adjustments and create a garment pattern with a more durable thread. In the fitting phase, the clothes lack every detail (even the pockets). So, it is impossible to test the functional aspect of the clothes, but you can only get a glimpse of the overall fit. To save time and cost, most people move on to the pattern-making phase directly after fitting. But in my case, as my designer pointed out, I kept moving from one pattern-making phase to another to make adjustments.

Repeatedly fixing in the pattern-making phase cost me a lot to create a final sample pattern that I could approve, and above all, it took a long time. But the baby carrier cover I wanted to make was a clothing that not only does its job, but also with a nice fit. Since pattern-making was a crucial step to develop well-made clothing, I wanted to fully test the pattern by wearing it myself in daily life and making adjustments based on my first-hand experience. This way, I was able to fix the shortcomings before our customers notice after the launch of the product, ensuring completeness of the product.

The shoulder line was fixed; but this time, we decided to lengthen the front layer of the cover which turned out too short.

While testing the sample for a dad, we found out there was not enough space inside when worn over a buckle-type baby carrier. So, we added a bigger size (Large) and made the total length of the cover longer and the neck size bigger.

After months of sample production and making adjustments, the Konny Baby Carrier Winter Cover finally saw the light. I was wearing short-sleeve shirts when I had been in and out of the sample room to develop the winter cover. But by the time I held the finalized sample in my hands, I was wearing an overcoat. I barely found a domestic factory and successfully started to sell the product from late October. And it was a big hit, selling out every time I produced them.

The first year of launching the Konny Baby Carrier Winter Cover, when I had to cameo as model because my model’s baby was sick.

I've seen many customers who were wearing the Konny Baby Carrier outside. But I haven't really seen my customers wearing the Konny Baby Carrier Winter Cover, as I spend most of my day at home working. But from the fact that all products made in the first season were sold out, I guess many of you nationwide are loving our product :)

The first thing I do each day at work is read the reviews of our customers. And I am moved by them everyday. “The winter loads are reduced by one third, for real. It’s amazing.” “I can tell that all Konny’s products are made by a mom who has fully dedicated her time to childcare and improved what had caused her inconveniences. Thank you so much!”

No, I thank you. Thank you, wholeheartedly.